B2B / Store Shipping System

keyboard_double_arrow_right

For warehouses aiming to optimize the cycle of picking and replenishment tasks!

The picking area for each product is one slot. Replenishment to the picking area (scheduled, urgent,

or post-picking)

can be done separately and concurrently with picking tasks.

For warehouses with multiple daily shipments, there's a need to avoid moving through multiple

locations during picking.

To meet this requirement, we developed a feature that allows users to check inventory data in the

storage location and

issue replenishment instructions to the main location near the shipping area with just a click of a

button.

* For food items, replenishment is done starting with the oldest expiration dates.

* For food items, replenishment is done starting with the oldest expiration dates.

keyboard_double_arrow_right

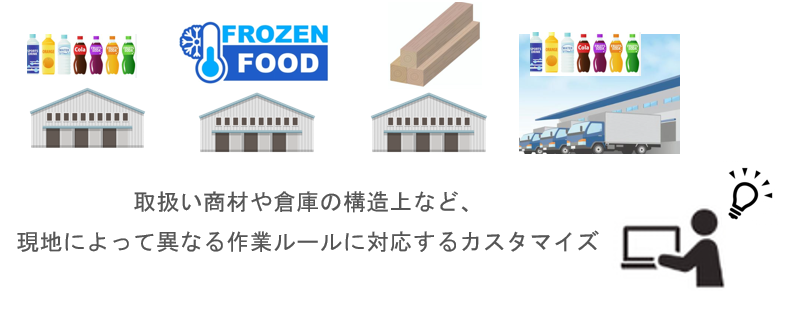

Customize continuously to match existing operations!

We tailor the app to match the specific needs of your operations, ensuring ease of use for employees

on their work

smartphones. Whether you need to request forklift operators for high-shelf replenishments, report

found items that

missed shelf placement, or pick items by shipping unit, our customizations cover all the details,

delivering high

cost-efficiency.

devices

Introducing the App Screens

Replenishment

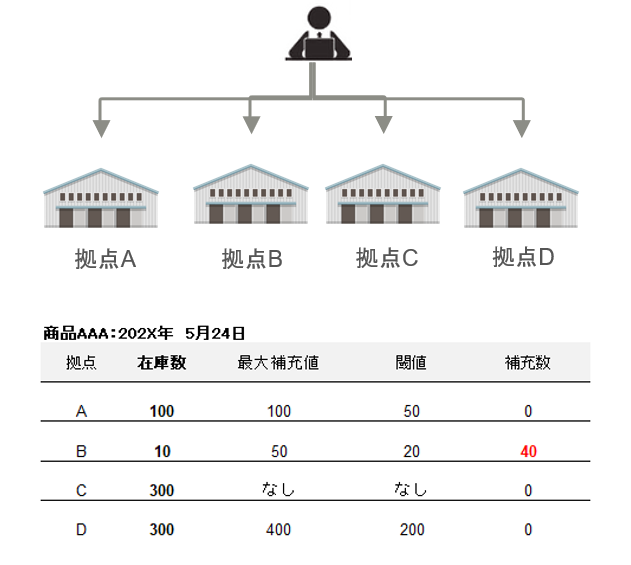

With just a click of a button, you can generate a replenishment list. There are two types of replenishment:

Regular Replenishment: Stocks are replenished up to the maximum threshold registered in the product master.

Emergency Replenishment: This applies to products without set thresholds, replenishing the quantity needed for shipments based on planned shipments and picking records.

With just a click of a button, you can generate a replenishment list. There are two types of replenishment:

Regular Replenishment: Stocks are replenished up to the maximum threshold registered in the product master.

Emergency Replenishment: This applies to products without set thresholds, replenishing the quantity needed for shipments based on planned shipments and picking records.

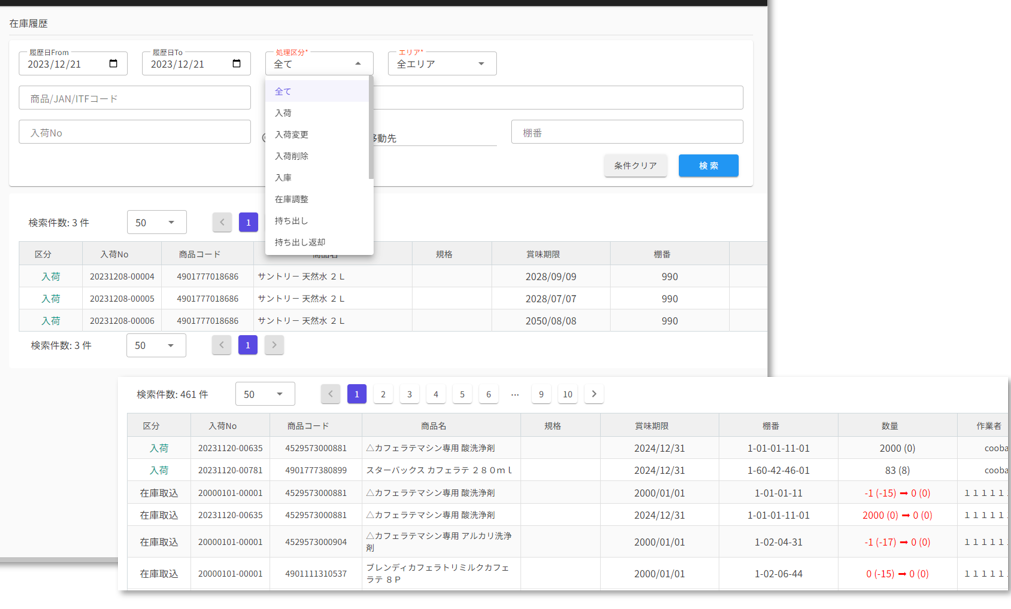

Inventory Adjustment

This is the confirmation screen for inventory history. You can review the history by type of operation. Inventory with quantity changes is highlighted in red, allowing you to quickly identify the recent changes.

This is the confirmation screen for inventory history. You can review the history by type of operation. Inventory with quantity changes is highlighted in red, allowing you to quickly identify the recent changes.

Inventory(Android)

We can handle unique operations such as replenishment requests, inventory transfers, and the discovery of unexpected inventory within the warehouse. The system automatically calculates cases and units based on the values inputted by the user.

We can handle unique operations such as replenishment requests, inventory transfers, and the discovery of unexpected inventory within the warehouse. The system automatically calculates cases and units based on the values inputted by the user.

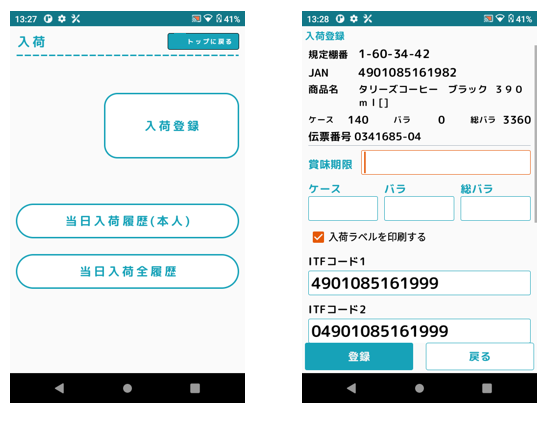

Inbound(Android)

You can verify tasks based on self/other categorization. If the product is under expiration date management, users perform expiration date registration. The system displays an alert if the inputted date does not match the conditions registered in the product master data.

You can verify tasks based on self/other categorization. If the product is under expiration date management, users perform expiration date registration. The system displays an alert if the inputted date does not match the conditions registered in the product master data.

library_books

List of Features

| Functionality | Details |

|---|---|

| Inbound | Inbound results and importing of inbound schedules |

| Replenishment | Replenishment list, creation of replenishment lists, excluded replenishment items list |

| Shipment | Importing shipping schedules, picking plan & results |

| Inventory | Inventory overview, inventory import, inventory history |

| Master | Product master with threshold settings |

| Order list | Shipping information list by order unit |

| Expiration date | Expiration date-based inbound, expiration date alert feature |

| Picking | Original picking by batch unit |

| Inventory discovery | Gathering inventory information found outside designated locations using a smartphone |

| Inventory in transit | Managing inventory during location moves |

| Replenishment Request | CSV output for issuing shipping labels by delivery company |

build

Customization Success Stories

- Can we accommodate the varying operational rules across multiple sites?

- Is it possible to access information across all sites through the cloud for confirmation?

- How can we efficiently manage both human and robotic work?

ー Customization Details ー

Wants:

Would it be possible to accommodate the different operational rules across multiple sites,

considering each warehouse

has its own set of regulations?

Customize:We offer comprehensive customization support, ranging from mobile app enhancements to the addition of features in the management interface. Our system provides flexibility to adapt to different operations across various sites within the same package.

Success!:

By accommodating varying operational rules, our system enables the implementation of digital solutions even in sites that previously relied on analog methods. This has helped prevent the personalization of tasks, ensuring consistency and efficiency across all operations.

Customize:We offer comprehensive customization support, ranging from mobile app enhancements to the addition of features in the management interface. Our system provides flexibility to adapt to different operations across various sites within the same package.

Success!:

By accommodating varying operational rules, our system enables the implementation of digital solutions even in sites that previously relied on analog methods. This has helped prevent the personalization of tasks, ensuring consistency and efficiency across all operations.

Wants:

We want to check information across all locations in the cloud.

Customize:Aggregate the package system information of each location in the cloud, allowing headquarters to view it collectively.

Success!:

Now, data from all locations can be checked from a single system, eliminating the need to log in to each location's system separately for verification.

Customize:Aggregate the package system information of each location in the cloud, allowing headquarters to view it collectively.

Success!:

Now, data from all locations can be checked from a single system, eliminating the need to log in to each location's system separately for verification.

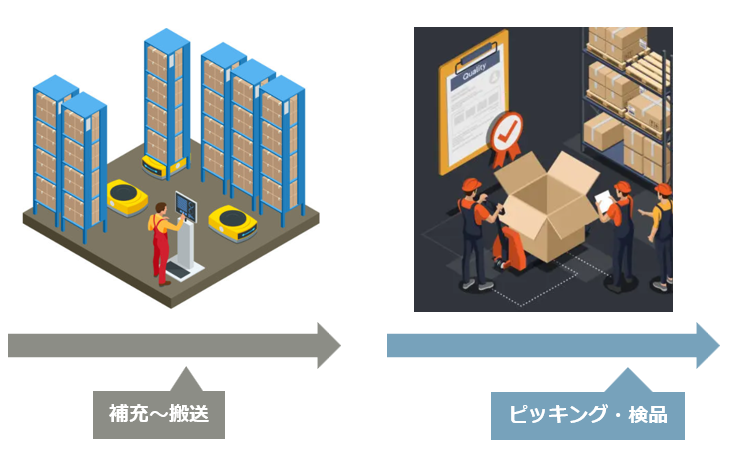

Wants:

We want to efficiently manage human work and robot work.

Customize:Provide separate functions for human work and robot work.

Automation for replenishment and transportation tasks is achieved through machinery (robots), while human work is limited to picking and inspection at the picking interface.

Success!:

Through collaboration with transport robots, our customers addressed labor shortages in warehouses and enhanced operational efficiency.

Customize:Provide separate functions for human work and robot work.

Automation for replenishment and transportation tasks is achieved through machinery (robots), while human work is limited to picking and inspection at the picking interface.

Success!:

Through collaboration with transport robots, our customers addressed labor shortages in warehouses and enhanced operational efficiency.