WMS compatible with store automatic ordering system

keyboard_double_arrow_right

Automatically delivery to the store in conjunction with the delivery schedule.

You can check the ordering and replenishment data from stores that are linked to the WMS as shipping

instructions, and start the shipping process immediately. It's also possible to automatically issue

shipping

instructions for services with predetermined delivery schedules, such as regular deliveries on

specific weekdays.

This eliminates the need for centralized coordination from headquarters or handling inquiries from

stores, allowing for quick delivery of products.

keyboard_double_arrow_right

Support various shipping methods such as direct shipping and store shipments to meet specific

requirements.

Our integrated shipping instructions, sourced from the automated store ordering system, encompass

directives for direct shipping, in-store dispatch, and returns. With the ability to review

instructions for each shipping

method, we ensure smooth handling and dispatching tailored to your needs. Real-time status updates

on shipping operations are shared between our systems and your stores, enabling full visibility of

shipment progress.

devices

Introducing the App Screens

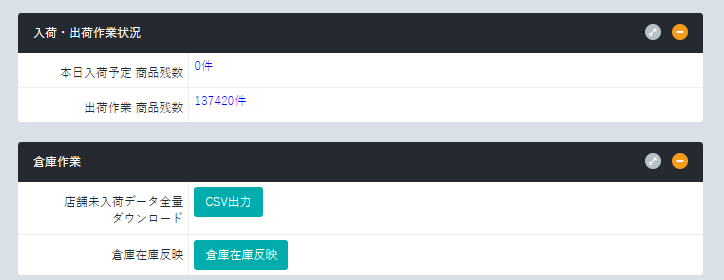

Dashboard

Display today's incoming and outgoing shipments as well as remaining product quantities on the top screen. Upon logging into the system, users can immediately see the day's status at a glance.

Download Pending Shipment Data and Sync Warehouse Inventory Right from Here!

Display today's incoming and outgoing shipments as well as remaining product quantities on the top screen. Upon logging into the system, users can immediately see the day's status at a glance.

Download Pending Shipment Data and Sync Warehouse Inventory Right from Here!

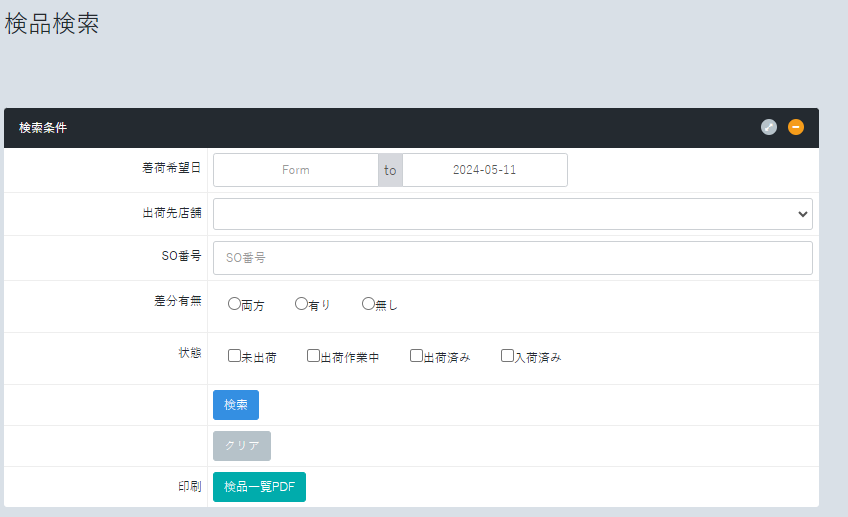

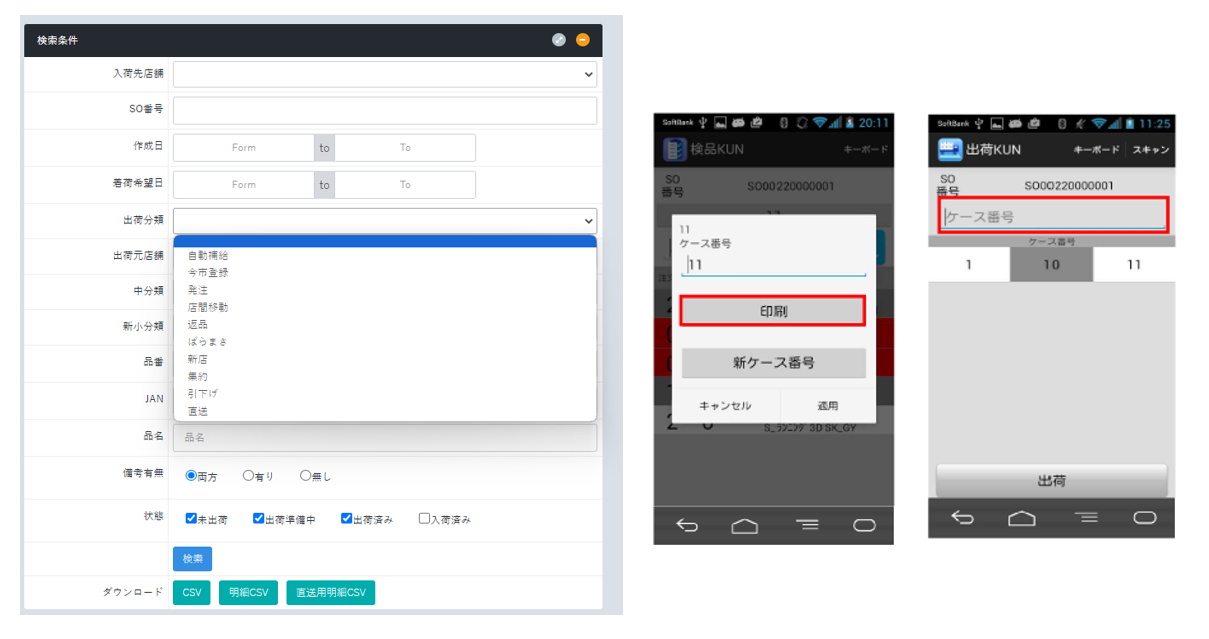

Inspection Search

Check inspection results. You can display the search results list by SO number and output it as a PDF for easy reference during the inspection process.

Check inspection results. You can display the search results list by SO number and output it as a PDF for easy reference during the inspection process.

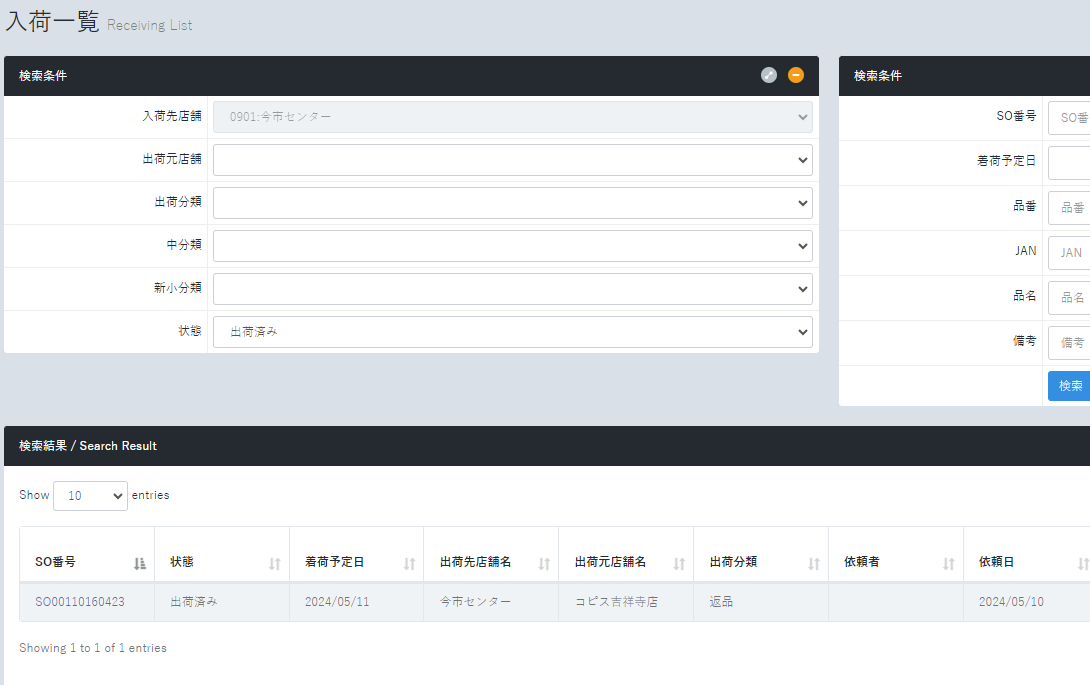

Incoming Shipment List

Handles the processing of incoming stock, including returns from stores.

Handles the processing of incoming stock, including returns from stores.

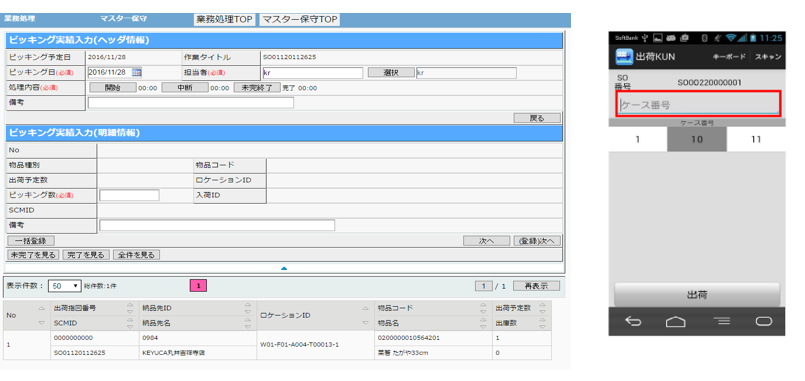

WMS Integration

Search for store order data (SO), download it as a CSV file, and register it in the WMS for scheduled shipments. Perform picking and shipping inspection tasks. Once the shipping inspection is complete, the shipment is marked as finished and the information is communicated to the store.

Search for store order data (SO), download it as a CSV file, and register it in the WMS for scheduled shipments. Perform picking and shipping inspection tasks. Once the shipping inspection is complete, the shipment is marked as finished and the information is communicated to the store.

Warehouse Shipping Task List

You can filter shipping tasks based on categories such as automatic replenishment from stores, individual order requests, and direct shipments. With the Shipping Barcode Label (SCM) feature, you can classify shipments by destination and process them accordingly.

You can filter shipping tasks based on categories such as automatic replenishment from stores, individual order requests, and direct shipments. With the Shipping Barcode Label (SCM) feature, you can classify shipments by destination and process them accordingly.

library_books

List of Features

| Functionality | Details |

|---|---|

| Inbound | Receive returned items from stores using your smartphone. |

| Inter-store Transfer | Create shipping instructions data specifying the destination store. |

| Direct Shipping | Support direct shipping requests from stores. |

| Inventory | Check both warehouse and store inventory, which includes reflecting sales inventory through POS integration. |

| Warehouse Functionality | Shipping and inspection (case/unit level support) tasks for data coordinated from the automated store ordering system. |

| SCM Label | Generate SCM labels based on inspection schedule data. |

| Inventory Count | Inventory count with additional attributes and sticky note functionality. |

build

Customization Success Stories

- Is it possible to automatically designate the shipping method for each shipment unit?

- Can we find a solution to the issues related to the loss of transit boxes and pallets used for shipments?

ー Customization Details ー

Wants:

Is it feasible to automatically designate the shipping method based on the shipper's preferences

and the constraints of

the transportation company?

Customize:Customize the system to allow for the automatic designation of the shipping method based on the shipper's preferences and the constraints of the transportation company. Depending on the origin and destination information, automatically select Yamato Transport or Sagawa. Additionally, add logic to choose mail delivery for items classified as small items if only one item is specified, and use regular delivery for other cases.

Success!:

By specifying the transportation company and shipping method based on the destination address and package size, it has become possible to reduce shipping costs.

Customize:Customize the system to allow for the automatic designation of the shipping method based on the shipper's preferences and the constraints of the transportation company. Depending on the origin and destination information, automatically select Yamato Transport or Sagawa. Additionally, add logic to choose mail delivery for items classified as small items if only one item is specified, and use regular delivery for other cases.

Success!:

By specifying the transportation company and shipping method based on the destination address and package size, it has become possible to reduce shipping costs.

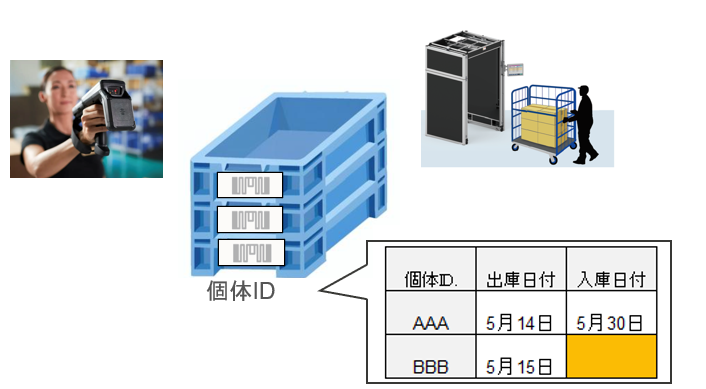

Wants:

Our customer wants to resolve the issue of not knowing the whereabouts of the transit boxes and

pallets

used for shipments.

Customize: Implement visibility of quantity and location using RFID tags. Introduce RFID tags and antennas. Implement logic to trace the whereabouts of equipment in coordination with shipping records, and integrate the data with WMS.

Success!:

By assigning RFID tags for identification, our customers can accurately track and manage which materials are shipped,when and where they are shipped, and how many are available. This enhanced visibility allows them to reduce additional purchasing costs due to losses and minimize emergency retrieval transportation costs resulting from material shortages.

Customize: Implement visibility of quantity and location using RFID tags. Introduce RFID tags and antennas. Implement logic to trace the whereabouts of equipment in coordination with shipping records, and integrate the data with WMS.

Success!:

By assigning RFID tags for identification, our customers can accurately track and manage which materials are shipped,when and where they are shipped, and how many are available. This enhanced visibility allows them to reduce additional purchasing costs due to losses and minimize emergency retrieval transportation costs resulting from material shortages.