Sheet/Roll Inventory Management System

keyboard_double_arrow_right

Calculate the maximum number of units that can be sold from a single resource when selling in fractional amounts, maximizing the profit rate.

When dealing with products that are cut from a single resource into various sizes and shapes, it's

no longer as simple

as "the number of purchased rolls minus the number of orders equals the available inventory."

Determining the available

inventory from a single roll becomes complex as it's uncertain how much inventory each size will

yield.

To address this, we calculate how many units of each size can be produced from the maximum area of

the uncut roll before

cutting. This information is then integrated into the e-commerce site as available inventory. By

showing customers the

inventory of all products derived from a single roll, we prevent potential sales losses.

keyboard_double_arrow_right

Flexibility to sell items individually, in bulk, or as part of a set.

This system enable handle scenarios where products are purchased in cases and sold in various

packaging options such as

bulk, individual units, or sets. By calculating how many units can be produced in each packaging

option, we determine

the optimal available inventory for each.

devices

Introducing the App Screens

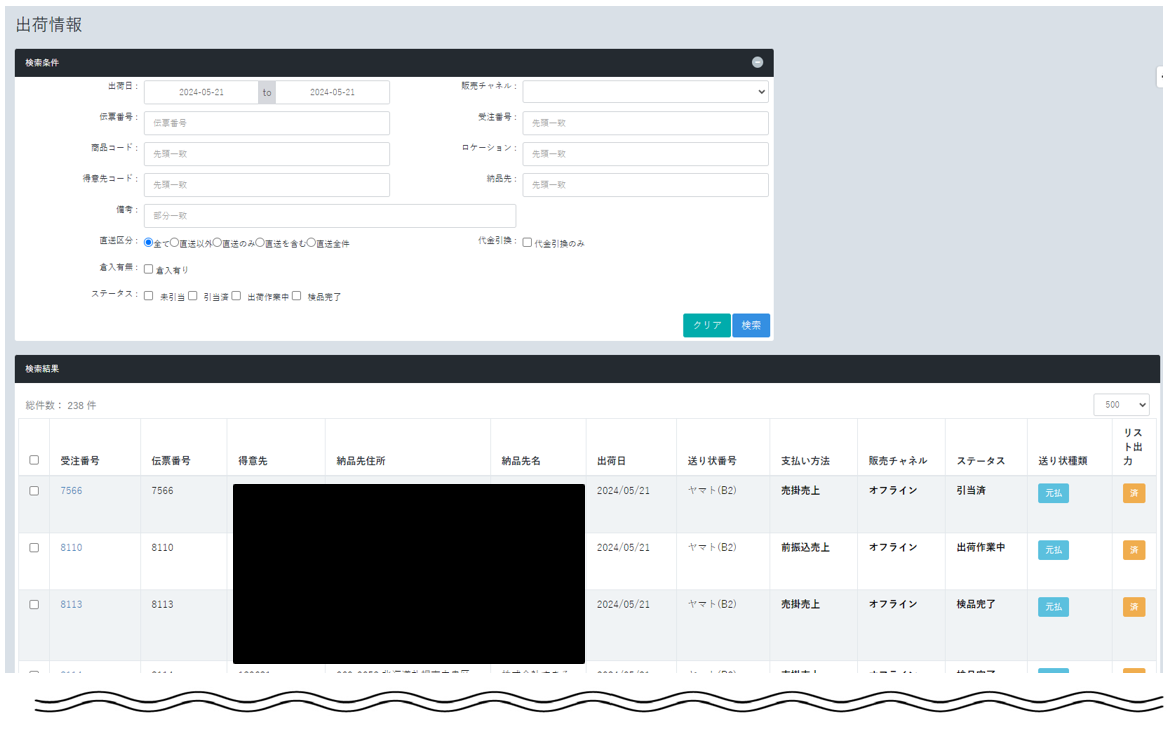

Sales integration

Sales data from both online and offline channels is linked by the sales management system and displayed as shipping instructions.

Sales data from both online and offline channels is linked by the sales management system and displayed as shipping instructions.

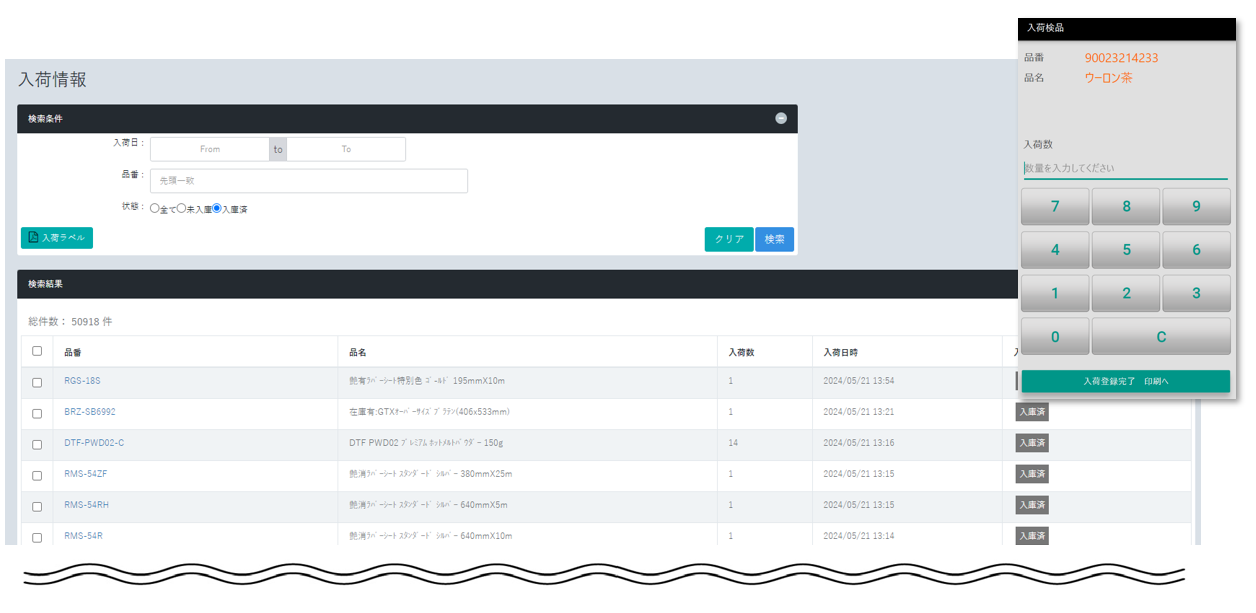

Receiving → Storing

Upon goods receipt completion, the product labels are automatically generated. These labels are then affixed to the products, and upon placement on the shelves, they are scanned with a smartphone to confirm the goods storage completion.

Upon goods receipt completion, the product labels are automatically generated. These labels are then affixed to the products, and upon placement on the shelves, they are scanned with a smartphone to confirm the goods storage completion.

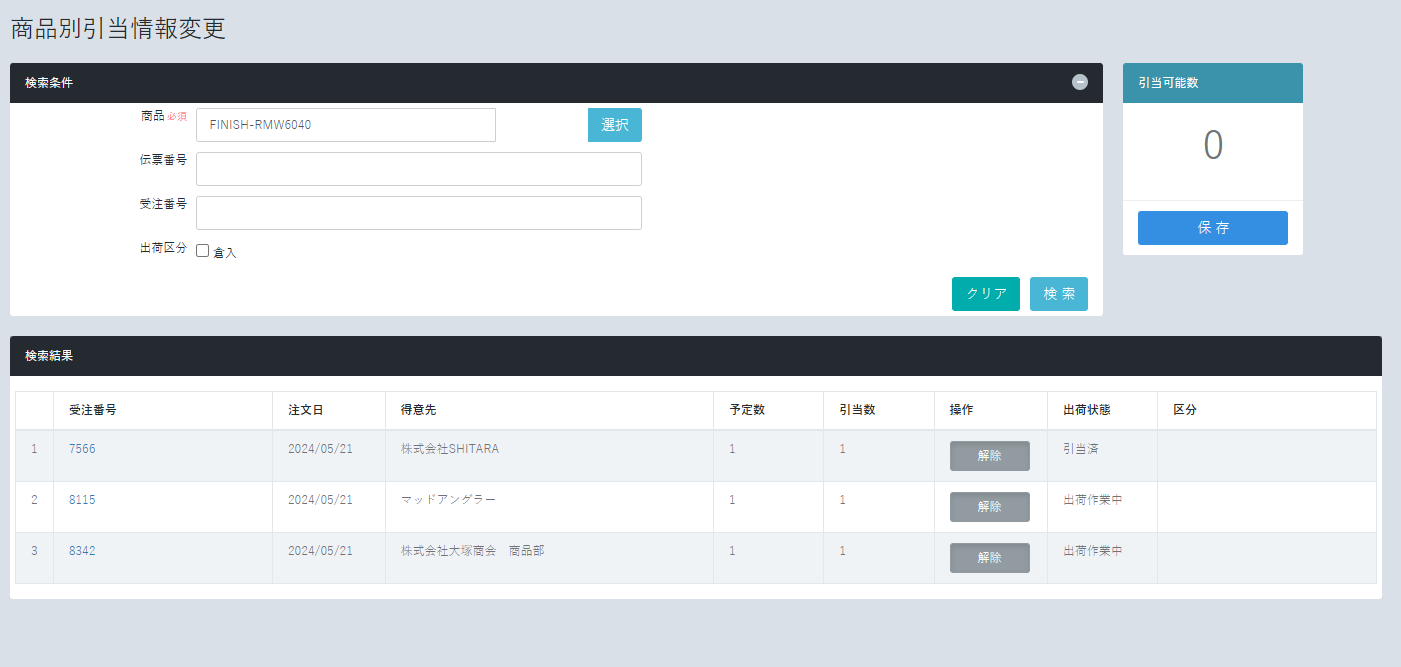

Allocation list by product

This is a screen for checking allocation status by product. When searching for a specific item, you can easily see the total allocatable quantity in relation to all orders. It's also possible to toggle between allocation and deallocation and to change the allocated quantity directly from this screen.

This is a screen for checking allocation status by product. When searching for a specific item, you can easily see the total allocatable quantity in relation to all orders. It's also possible to toggle between allocation and deallocation and to change the allocated quantity directly from this screen.

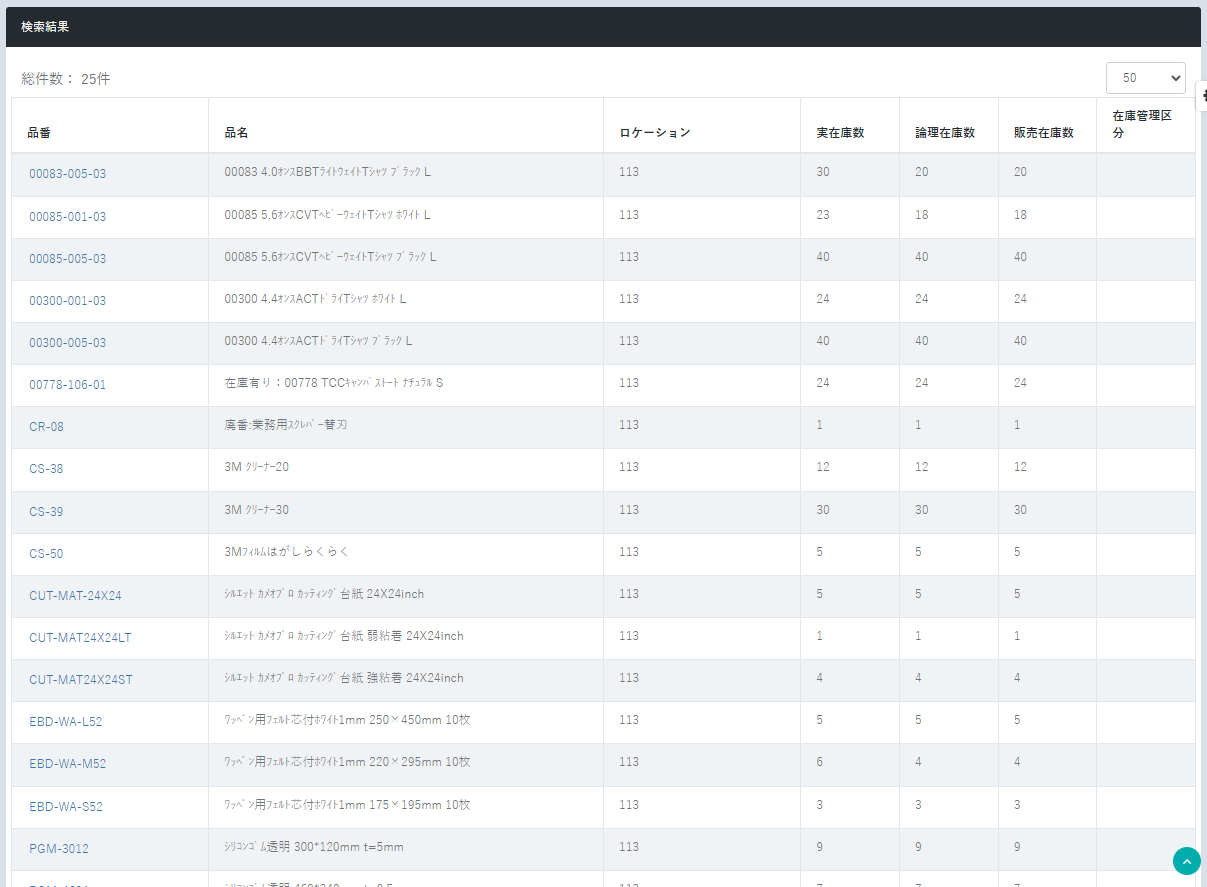

Calculation of Logical Inventory for Sales

You can quickly check the actual inventory, logical inventory, and available inventory for sales at a glance.

You can quickly check the actual inventory, logical inventory, and available inventory for sales at a glance.

Processing Instructions

If there is no actual inventory for the items on the picking list, cutting instructions for the raw material will be generated.

If there is no actual inventory for the items on the picking list, cutting instructions for the raw material will be generated.

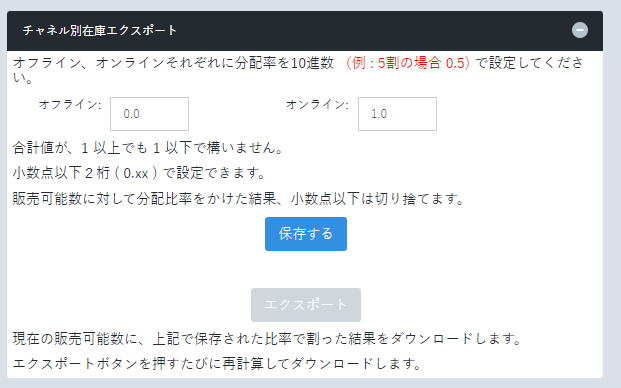

Offline Inventory: Online Inventory Allocation Ratio

Inventory transfer between offline and online is possible. At the end of each day, inventory is automatically reallocated based on the default settings.

Inventory transfer between offline and online is possible. At the end of each day, inventory is automatically reallocated based on the default settings.

library_books

List of Features

| Functionality | Details |

|---|---|

| Goods Receiving and Storage | Inspect and label received goods in the warehouse using a smartphone. |

| Shipment | Output picking lists, inspect shipments with a smartphone, and download CSV files for integration with the shipping label issuance system. |

| Output of processing instructions | Output cutting instructions for the raw material. |

| Unshipped List | Summary of shipment information where allocation of products has not been completed due to insufficient actual inventory. |

| Order List | Shipping information list by order unit |

| Allocation list by product | A list of reservation status by product. |

| Inventory | Inventory inquiry, Inventory adjustment |

| Inventory settings by channel | Setting the ratio of offline and online stock |

| Master for Calculating Available Inventory | Product master for calculating available inventory by type: raw material (area), set product inventory, and disassembled product inventory. |

| Integration with the Next Engine | Integrate shipped data with Next Engine to automatically update information across multiple e-commerce sites. |

| Integration with the Shipping Label Issuance System | CSV Output for Shipping Label |

| Issuing various labels | Product code QR, arrival label |

| Inventory Count | RFID compatible, tagged inventory, inventory label printing function |

build

Customization Success Stories

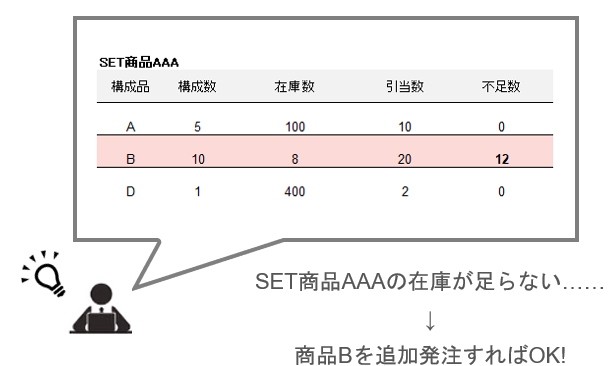

- If the inventory of set products is 0, which individual products are insufficient?

ー Customization Details ー

Wants:

When the inventory of set products is 0, We want to quickly identify which individual

products are insufficient.

Customize:We have added a screen to display the inventory of each component (individual product) and a CSV export feature.

Success!:

Now that it's possible to visualize which individual products are lacking when the theoretical inventory of a set product is zero or minimal, the confirmation process for procurement has been streamlined, reducing the workload.

Customize:We have added a screen to display the inventory of each component (individual product) and a CSV export feature.

Success!:

Now that it's possible to visualize which individual products are lacking when the theoretical inventory of a set product is zero or minimal, the confirmation process for procurement has been streamlined, reducing the workload.